YX

Common type contact pressure gauge

Suitable for measuring gas and liquid without corrosion on copper and copper alloys Body pressure. |

|

YXC

Magnetic assistant type common contact pressure gauge

Suitable for measuring gas and liquid without corrosion on copper and copper alloys

Body pressure.

The YXC contact pressure gauge is compared with the YX contact pressure gauge

It has the characteristics of high rated power, reliable transmission, long contact life and so on

It has certain anti-vibration performance. |

|

Electric contact pressure gauges are widely used in petroleum, chemical industry, metallurgy, power stations, machinery and other industrial sectors or mechanical and electrical equipment

Measure the pressure of all kinds of fluid medium without explosion danger.

Usually, the instrument is connected with the corresponding electrical device (such as relay and frequency converter)

When used together, all kinds of gas and liquid media under test (control) pressure can be automatically controlled and sent (report) by instruments

The purpose.

The product application

On the electric contact signal needle of the electric contact pressure gauge device, there is adjustable permanent magnetic steel, which can increase the contact suction.

Accelerate contact action, so that contact reliable, eliminate arc, can effectively avoid the instrument due to working environment vibration or interface

The pulsation of mass pressure causes frequent shut-off of contacts.

So the electric contact pressure gauge has reliable action, long service life and contact switch

High power and other advantages.

Structure principle

The contact pressure gauges are composed of a measuring system, a indicating system, a magneto-assisted electrical contact device, a housing, an adjusting device and a junction box (insert)

Head), etc.

general electric contact pressure gauge:

Used to measure the positive and negative pressure of gas and liquid media which have no corrosion effect on copper and copper alloys;

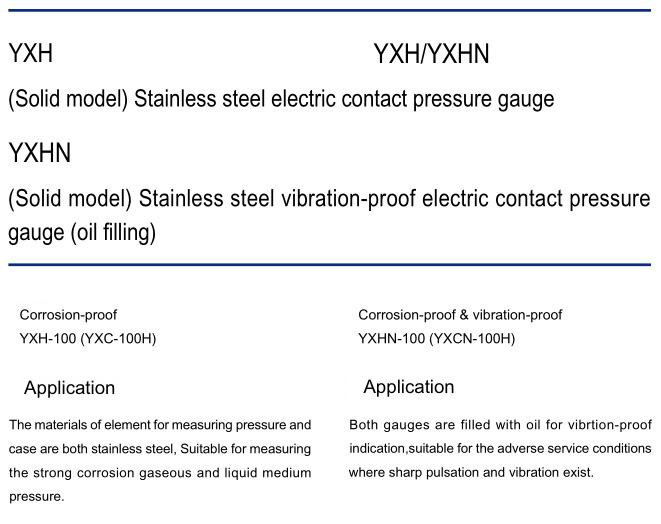

stainless steel electric contact pressure gauge:

It is used to measure the positive and negative pressure of gas and liquid media which have no corrosion effect on stainless steel

The signal is out and the control circuit is connected to achieve the purpose of automatic control alarm.

The contact pressure gauge is based on the measurement system of the spring tube under the pressure of the measured medium, forcing the end of the spring tube to produce phase

The elastic deformation should be a displacement by means of a pull rod driven by a gear drive mechanism and amplified by an indication (link) on the fixed gear

The measured value is indicated on the dial one by one.

At the same time, when it is connected to a contact (upper or lower limit) on the set pointer

The instantaneous contact (break or break) of the phase, causing the circuit in the control system to be disconnected or connected to achieve automatic control and

The purpose of sending an alarm. |

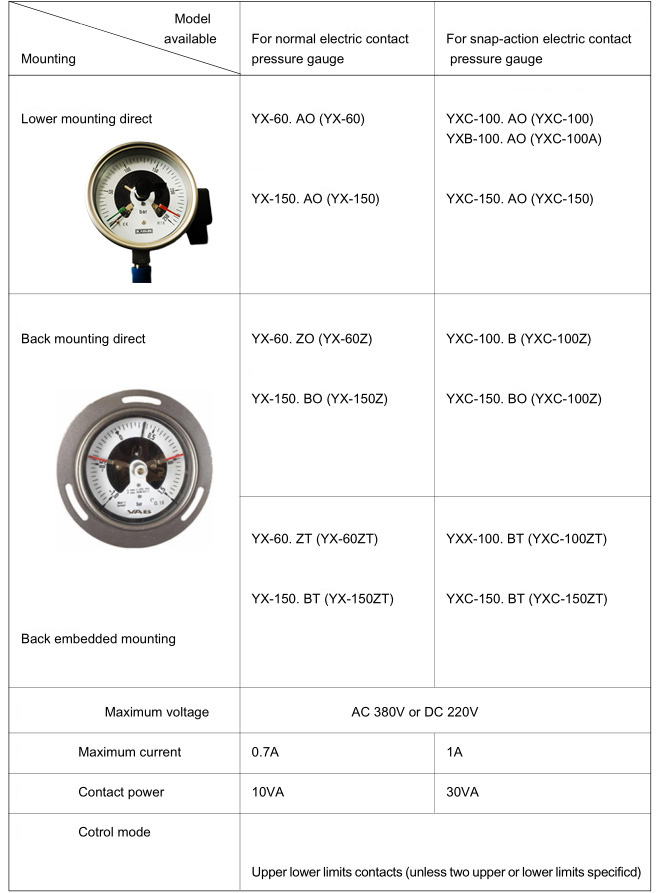

installation

1. Radial direct installation

2. Direct axial installation

3. Direct installation of radial front edge

4. Install the front side of the axial belt directly

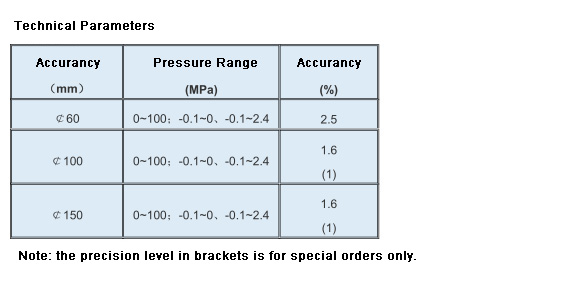

Contact electrical parameters

maximum power: 30 w

use working temperature: 25 ¡æ ~ 55 ¡æ

work pressure limit: no greater than 2/3 of the upper limit value of the instrument

work environment vibration frequency¨Q 25Hz, amplitude ¨Q 0.5 mm

Product categories

In view of this series of instruments not only have novel design, reliable structure, complete varieties and specifications, good stability and adaptability

Besides strong features, it also has the advantages of simultaneous measurement and control, simple installation and small maintenance, etc. Therefore, it is generally without instructions.

Pressure measuring and controlling instrument without switching adjustment and without external setting device is incomparable to pressure controller.

In order to meet the different test objects (there are requirements for shock resistance, corrosion resistance and explosion protection, etc.), the required shock resistance electrical contact points can be selected

Pressure gauges or corrosion-resistant electrical contact pressure gauges and explosion-proof electrical contact pressure gauges.

ordinary electric contact pressure gauge

It is suitable for measuring the pressure of gas and liquid without corrosion on copper alloy and iron.

anti-corrosion type electric contact pressure gauge

The main pressure measuring elements and meter shells are made of stainless steel, suitable for measuring corrosive gas and liquid pressure force

The anti-corrosion type seismic electric contact pressure gauge

It is suitable for measuring the strong pulsation of medium and environmental vibration by filling the inner body with oil and using liquid damping to ensure no vibration display

explosion-proof electric contact pressure gauge

It is suitable for dangerous places with explosive mixtures in the environment.

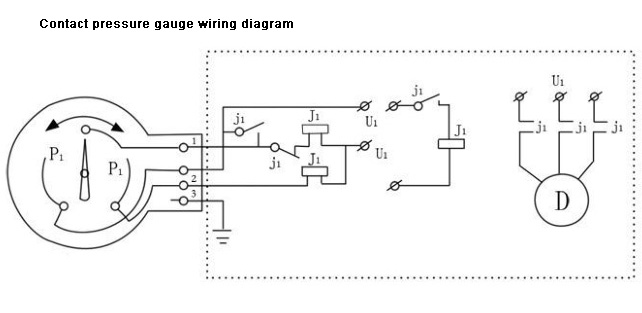

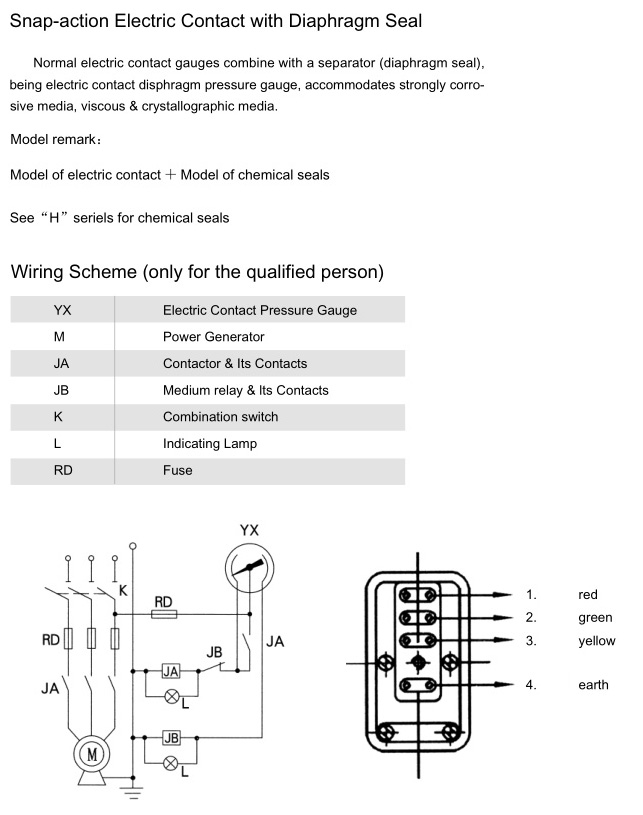

Electrical principle

Take the compressor motor as an example: when the pressure of gas storage irrigation reaches the lower limit, it will open automatically and stop automatically when it reaches the upper limit.

The control process is as follows: when the pressure reaches (or is low when starting) the lower limit, the contact pressure gauge's movable contact (power supply)

The common end) is connected with the lower contact, and the relay J1 moves and locks itself. Its normally open contact is closed to drive J3, and the motor can be operated electrically Turn.

When the pressure reaches the upper limit, the movable contact is connected to the upper limit contact, and the relay J2 ACTS. Its normally closed contact is disconnected and cut off

Power supply of J1 is cut off, its normally open point is cut off, J3 is released, and the motor is stopped.

So reciprocate, achieve the goal of automatic control.

Answer the liquid material

Copper alloy, 304 stainless steel or 316 stainless steel.

verification

The electric contact pressure gauge is actually a circuit switch operated by the pressure gauge. It is just a signal of electric contact on the ordinary pressure gauge

Equipment, therefore, the pressure part of the test and normal pressure gauge are the same, but after the pressure part of the test is qualified, it still needs to be increased

Verification of the electrical contact signal device.

electric contact pressure gauge verification steps

1. Install the pressure gauge on the calibrator, and use the needle extractor to push the two signal contact Pointers beyond the upper limit and the lower limit respectively, and then enter

Perform value verification.

2. After the verification of the indicator is qualified, the signal contact Pointers of the upper limit and the lower limit are respectively set at more than three different inspection points to slow down

Slowly increase or decrease the pressure until the signal is instantaneous, when the standard pressure gauge reads and the signal pointer

The deviation between the values indicated shall not exceed the absolute value of the allowable basic error.

Frequently asked questions

electric contact pressure gauge of signal either early or late

The contact position is not correct or the contact metal rod is loose.

The contact position is not correct and the contact correction is vertical until the appropriate signal occurs.

When the metal rod of contact is loose, it should be fixed firmly. If it is slight, the proper amplification of the filament should be adopted to increase the anti-torque of the filament, which is also effective Fruit.

signal electric contact device will not occur

Too dirty contact;

The insulation layer of the signal device is damped;

Circuit failure, etc.

If the contact is too dirty, use sandpaper to remove the dirt.

When the insulating layer is damp, dry it with hot wind.

The circuit is out of order and should be found and repaired. |

The electric contact pressure gauge has three connections, one is for public use, the dial needle is adjustable, one can be adjusted to 0.4m.

Connect the low voltage start control relay, another dial to 0.6M, connect the high voltage stop relay, the common line is high voltage control

The common line.

The upper pointer is the upper limit, the lower pointer is the lower limit, and the middle black pointer indicates the actual pressure value.

The actual

When the pressure is above the upper limit, connect with the upper limit and disconnect from the lower limit.

When the actual pressure is between the upper and lower limits, the common end and the upper limit,

The lower limit is off.

When the actual pressure is below the lower limit, the common end is connected to the lower limit and the upper limit is disconnected

It is used to control the upper and lower pressure.

It is not enough to have electric contact pressure gauges, but also an automatic control box to control the pump.

Add an intermediate relay. The contact pressure gauge has a high voltage point, a middle point, a low voltage point, and the current direction:

The fire wire enters the middle point, passes through the low voltage point, arrives at the normal closing point of the contact point set of the intermediate relay 1, reaches the end of the contactor coil, the relay line

Connect the other end of the circle to the zero line.

Select a different set of contacts on the normally open contacts, 2 end parallel to the pressure gauge low pressure end and the middle point end. |

|