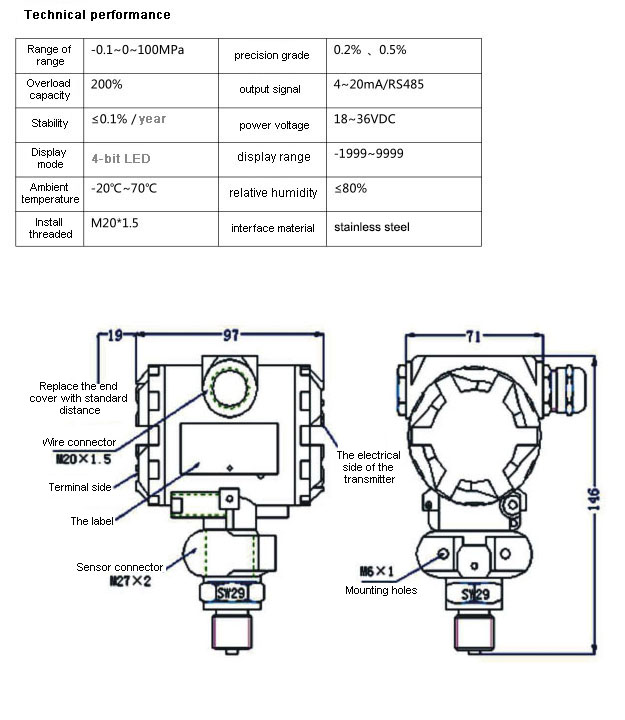

QYB102 series pressure transmitter, using imported sensor pressure sensitive components, with computer laser resistance adjustment

Temperature compensation, using integrated junction box design.

Special terminal and digital display, installation, calibration and maintenance

Convenient.

This series of products are suitable for petroleum, water conservancy, chemical industry, metallurgy, electric power, light industry, scientific research, environmental protection and other enterprises

Business units, to achieve the measurement of fluid pressure and apply to all kinds of occasions around the clock environment and corrosive fluid.

The main features

various range selection;

digital display, liquid crystal pressure;

range debug is convenient;

reverse polarity protection and current limiting protection;

lightning resistance, impact resistance;

intrinsically safe explosion-proof;

Small size, beautiful appearance, high cost performance;

high precision, high stability, high reliability; |

กก

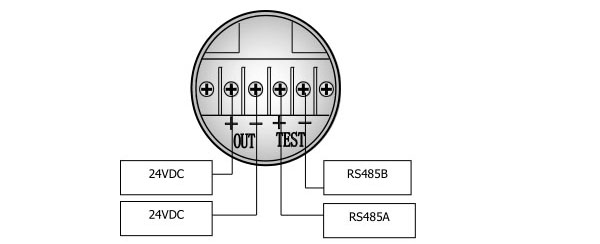

Electrical wiring

The signal terminals are set in separate compartments of the electrical box.

When wiring, may screw down the wiring side of the meter cover.

The power is through

If the signal wire is connected to the transmitter, no additional wiring is required |

The signal line can be double stranded.

In the case of serious electromagnetic interference, it is recommended to use shielded wires and properly grounded.

The signal wire should not pass through the metal pipe together with other power cables or in the same line slot, nor should it pass near the strong power equipment.

The threading hole on the electrical shell of the transmitter shall be sealed or plugged (with sealant) to avoid moisture in the electric shell

Accumulation.

If the threading hole is not sealed, when installing the transmitter, the threading hole should be facing down to remove the liquid.

The signal wire can also float or be grounded at any point in the signal loop, and the transmitter case can also be grounded or ungrounded.

Because the transmitter is grounded by capacitive coupling, when checking the insulation resistance, you cannot use a megometer above 100V.

The circuit shall be checked at a voltage not greater than 45V.

Matters needing attention

1. Please make correct connection according to the wiring method shown in the figure.

If the connection is reversed, there will be no signal due to the protection measures adopted inside the transmitter

The output.

The transmitter can work when the power is connected, but the output signal after preheating for 30 minutes is stable and reliable.

2. The transmitter is used in a non-corrosive medium for silicon and stainless steel (except special anti-corrosion type).

3. The maximum pressure of the system measured shall not exceed the rated overload value, and the back pressure end of the transmitter shall not be directly connected with the conductivity.

Corrosive liquid or gas, liquid level sealing type air guide cable air guide hole can not be blocked.

4. It is strictly prohibited to extend the sharp and hard things into the pressure output hole

A collision.

5. This product is a precision primary measuring instrument, and it is strictly prohibited to fall and hit at will, firmly grip, disassemble or use sharp metal tools

With a prick hole.

6. The instrument shall be installed in a ventilated, dry, corrosion-free and shady place as far as possible.

If the site environment is bad, appropriate measures should be taken

Apply protective instruments.

7. Abnormal output and stop inspection. If the product quality problem is caused, return to the factory for maintenance together with the warranty card and the operation manual

And giving a refund or an exchange.

8. Non-professional personnel shall not open the instrument circuit board or change other devices. |

กก

|